SR (SOLVENT RECOVERY)

A solvent recovery facility (SR) is a facility that absorbs a water-soluble solvent or a high boiling point solvent into a high concentration solution.

Water is mainly used as a solvent, and sometimes high boiling point absorbent is also used. SR includes water-soluble solvents such as NMP, DMAC, DMF, and semiconductors, paints, and resin manufacturing plants.

High boiling point solvents can be recovered. The solvent recovery efficiency is more than 95%, and the recovered solvent concentration can be designed to be more than 40 wt% to 99 wt%.

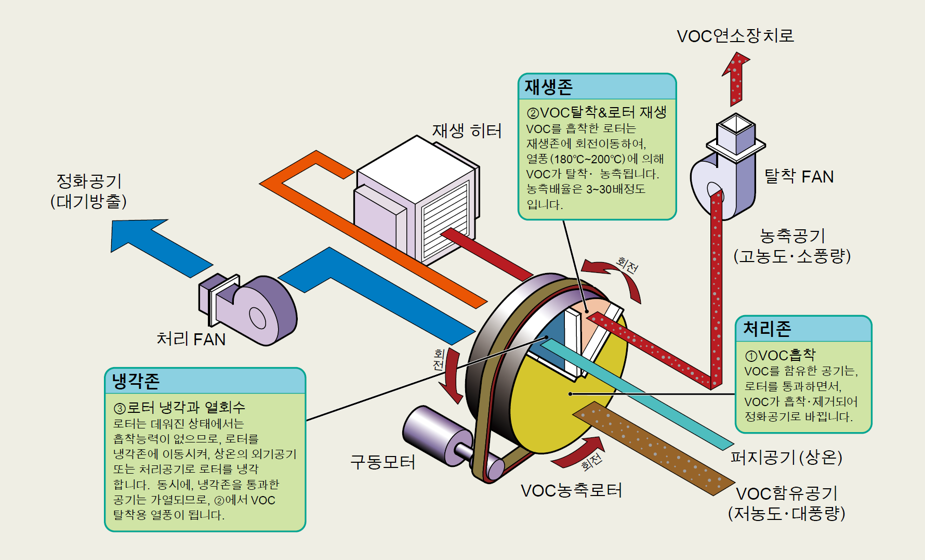

The low-concentration high-wind solvent is concentrated in a high-concentration excursion amount using a concentration device using activated carbon and zeolite, and the treatment efficiency is improved in combination with the solvent recovery facility.

01

SR operating principleVOC gas discharged from the process is absorbed into water or absorbent to recover. To increase the absorption efficiency, fillings that increase the contact area between the absorbent and VOC gas are used. In this process, the concentration of VOC gas is absorbed and discharged at the concentration of circulating fluid and gas-liquid equilibrium. The primary absorption-treated low-concentration VOC gas undergoes a secondary absorption process to treat the final emission concentration below the standard. VOC gas that has undergone a secondary absorption process is discharged below the standard value into the atmosphere. Piling, tray, structured packing, etc. are utilized for filling, and the number of steps, the number of beds, and the height of the filling are determined by efficiency.

02

SR Design processIn the design stage, the basic design is carried out by identifying whether cooling devices are needed and appropriate fillings according to the discharge gas flow rate, temperature, concentration, and physical properties. Our company is designed for optimal recovery efficiency and high concentration. In the case of low-concentration gases, it is designed to reduce investment and utility costs by utilizing concentrators.

Absorption type

In the case of hydrophilic solvents such as NMP, water is used as an absorbent to recover. It is an economical, fire risk-free, and easy to maintain facility.

Adsorption tower

After adsorption using an adsorbent such as activated carbon and zeolite, it is desorbed and recovered. The recovered high-concentration gas can be treated in combination with an absorption facility, or it can be recovered by cooling after steam desorption. It is suitable for low concentration and easy to recover after desorption, and requires economic review because it requires a lot of energy in the desorption process. In general, it is mainly used for solvent recovery with high unit price.